Watson-Marlow Fluid Technology Solutions (WMFTS) highlights its range of pumps ideal for

a variety of manufacturing processes used in producing lithium-ion batteries for electric

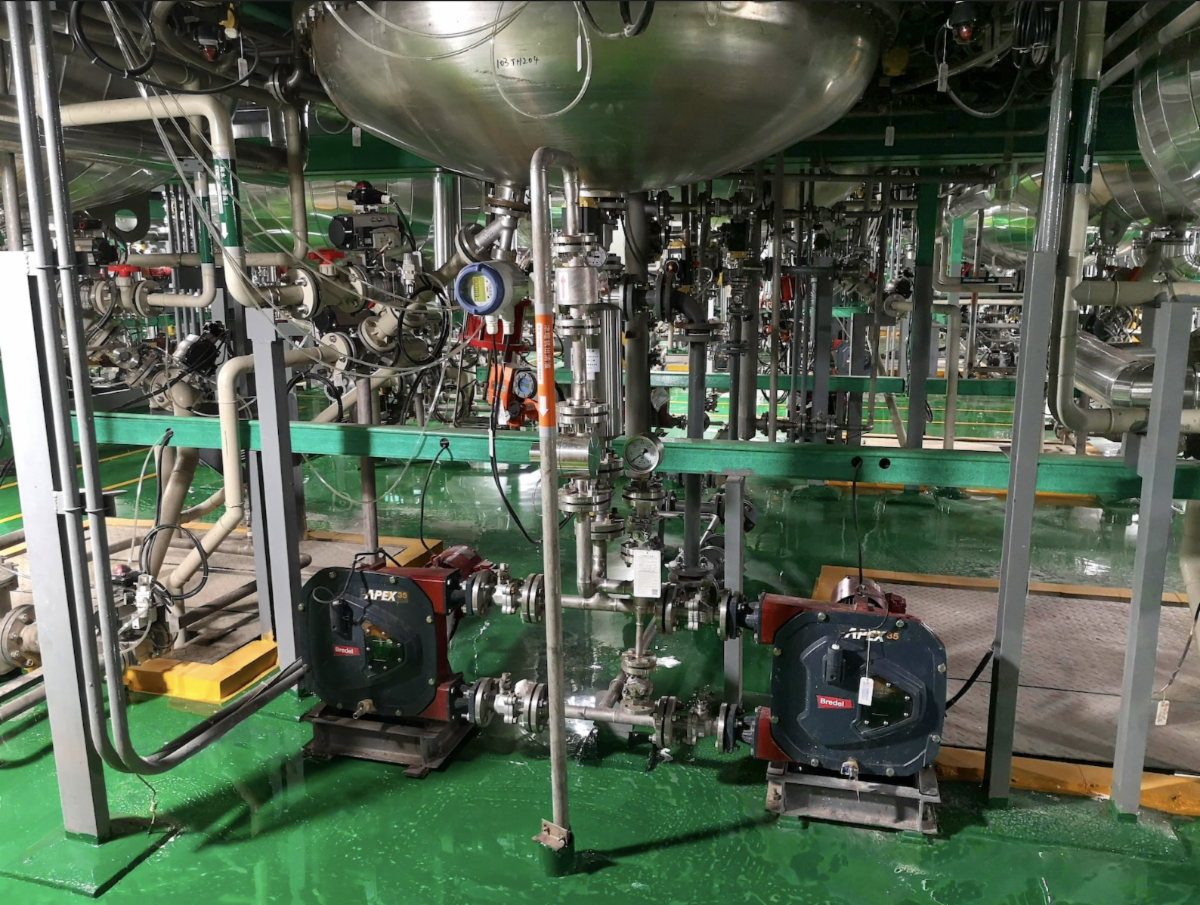

vehicles. On offer are Bredel hose pumps and Bredel APEX products, which provide

constant production cycle efficiency and help manufacturers meet ever-more demanding

battery production schedules.

Watson-Marlow Fluid Technology Solutions (WMFTS) highlights its range of pumps ideal for

a variety of manufacturing processes used in producing lithium-ion batteries for electric

vehicles. On offer are Bredel hose pumps and Bredel APEX products, which provide

constant production cycle efficiency and help manufacturers meet ever-more demanding

battery production schedules.

Bredel hose pumps are ideal for use in the ball milling process used in manufacturing

lithium iron phosphate (LiFePO4) batteries. Unlike older air-operated double-diaphragm

pump (AODD) pump technology, Bredel hose pumps are not affected by slurry viscosity,

which ensures greater production cycle efficiency. The pumps run at 20 revolutions per

minute in continuous 24/7 operation as part of a computer-controlled process. The Bredel

pump also reduces wear to the ball/seats that can result in leakage, causing increased

downtime and repair costs.

Bredel APEX hose pumps are ideal for use in transferring liquid chemicals from raw material

tanks to reaction tanks at stable flow rates for production of battery-grade cobalt tetroxide

and high-purity battery-grade cobalt sulphate. The pumps are designed to operate 24 hours

for 7-10 day periods and are supplied with optimum hose elements. With their seal-less,

valve-less design, APEX pumps are engineered for a more competitive price/performance

ratio in comparison with high-pressure hose pumps and are designed to suit all dosing,

metering and transfer applications with unmatched flow stability.