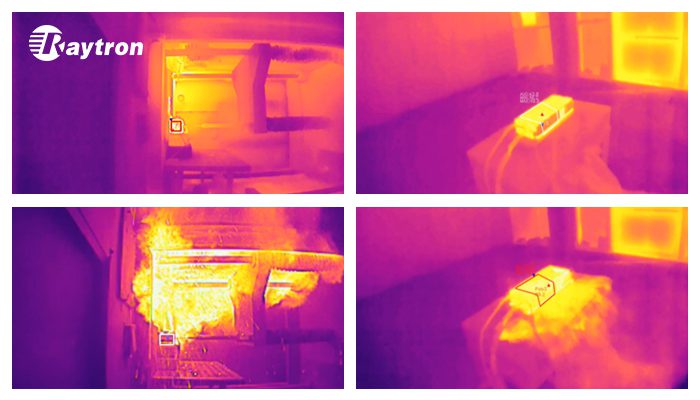

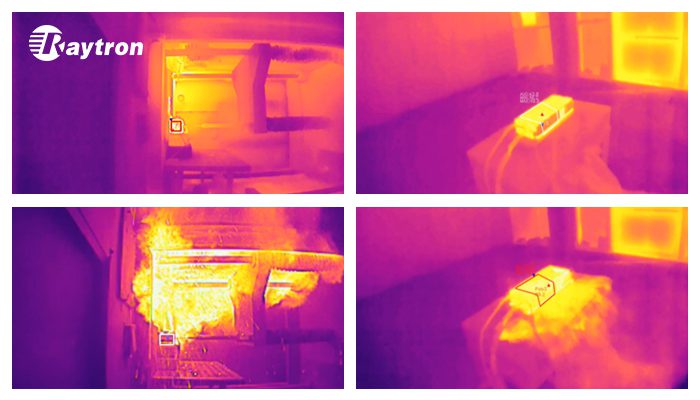

Infrared thermal imaging firm Raytron has unveiled its new thermal imaging technology for monitoring the lithium-ion battery lifecycle to prevent thermal runaway failures.

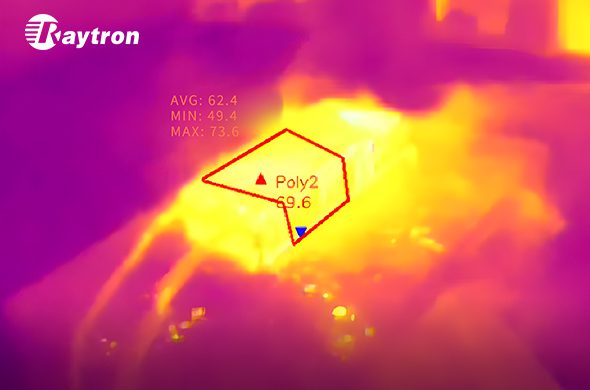

Infrared thermal imaging is a non-contact technology that can provide the necessary real-time, visual temperature data to intervene before a full-blown lithium battery fire is triggered. At the early signal detection, the thermal imaging identifies minute hotspots, which are early indicators of internal shorts, high-resistance connections or cooling failures.

The system can analyze temperature rate-of-rise patterns to provide predictive warnings, boosting the performance of traditional battery management systems, according to the company.

In R&D, infrared thermography cameras validate BTMS and structural safety by capturing heat propagation during stress tests, allowing engineers to design effective containment against thermal runaway battery spread.

During production, Raytron’s TN220 thermographic cube camera is used for quality control. It screens out high-risk cells that have micro-shorts or welding defects by detecting abnormal heat during fast charge/discharge, eliminating latent failure points.

In logistics, 24/7 thermal imaging scanners monitor warehouses for spontaneous hot spots, ensuring early intervention to prevent a lithium fire.

For after-sales service, handheld thermography cameras enable maintenance crews to quickly locate faulty cells or high-resistance connections, stopping minor heat anomalies from escalating into a full thermal runaway event.

Source: Raytron

Source link by Charged EVs

Author Nicole Willing

#Raytron #develops #thermal #imaging #tech #battery #thermal #runaway #prevention