Audi is embracing its future in China with the launch of a new Chinese market electric sub-brand called AUDI that ditches the iconic “four rings” logo in favor of four capital letters – but one thing it hasn’t ditched is AUDI Audi’s sexy teutonic long-roof design language.

As you might expect from an Audi-issued press release that claims AUDI is a new and distinctive thing that’s totally separate from Audi, it’s a difficult and confusing read. Check out this sample and you’ll see what I mean:

The first premium car brand to enter the Chinese market back in 1988, Audi was a pioneer. As it launches its new brand AUDI in cooperation with SAIC, the company now underlines its claim to this role. AUDI is shaped 100-percent by the Audi DNA and embodies “Vorsprung durch Technik” in the era of electric intelligent connected vehicles. The AUDI E concept car was jointly developed by experts from both Germany and China. It offers a preview of three future production models to be introduced from mid-2025.

Which – I dunno. Maybe you’re smarter than me and this all makes sense. Regardless, Audi seems serious about this new AUDI thing, and the first vehicle to debut wearing the new nameplate does seem to share in the Audi DNA we’ve come to know, if only because it’s an AWD wagon and not a more generically-shaped SUV.

The AUDI E concept, itself

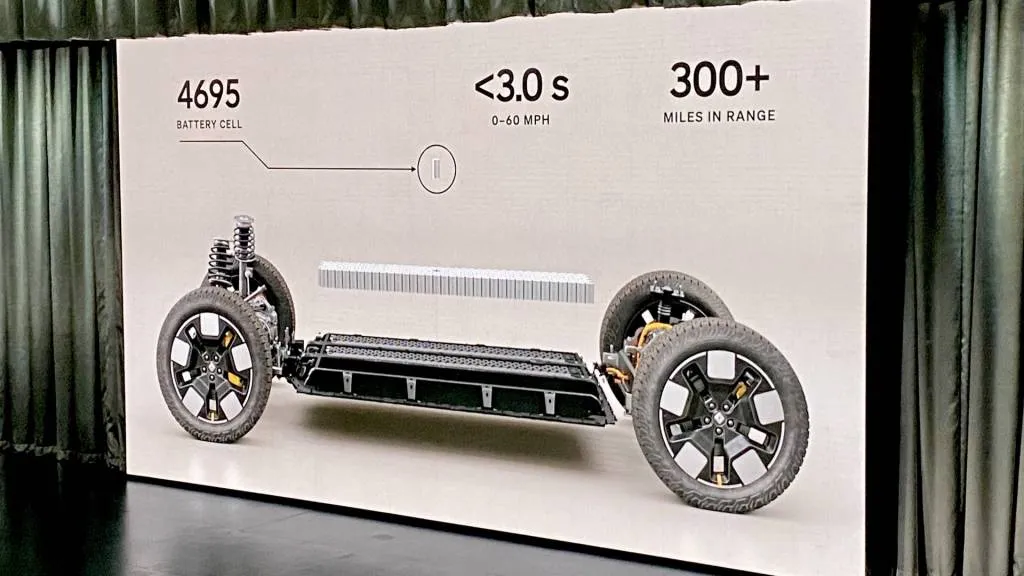

Co-developed with Chinese auto giant SAIC, the AUDI E Concept is about 4.8 meters long, putting it squarely in that BMW 5-series, Mercedes-Benz E-class range typically inhabited by the A6. Powered by two electric motors (one at each axle) putting out 570 kW (~765 hp) and 800 Nm (590 lb-ft) of torque to the ground through “signature” Audi quattro four-wheel drive, which enables the AUDI to rocket from 0-60 mph in about 3.5 seconds.

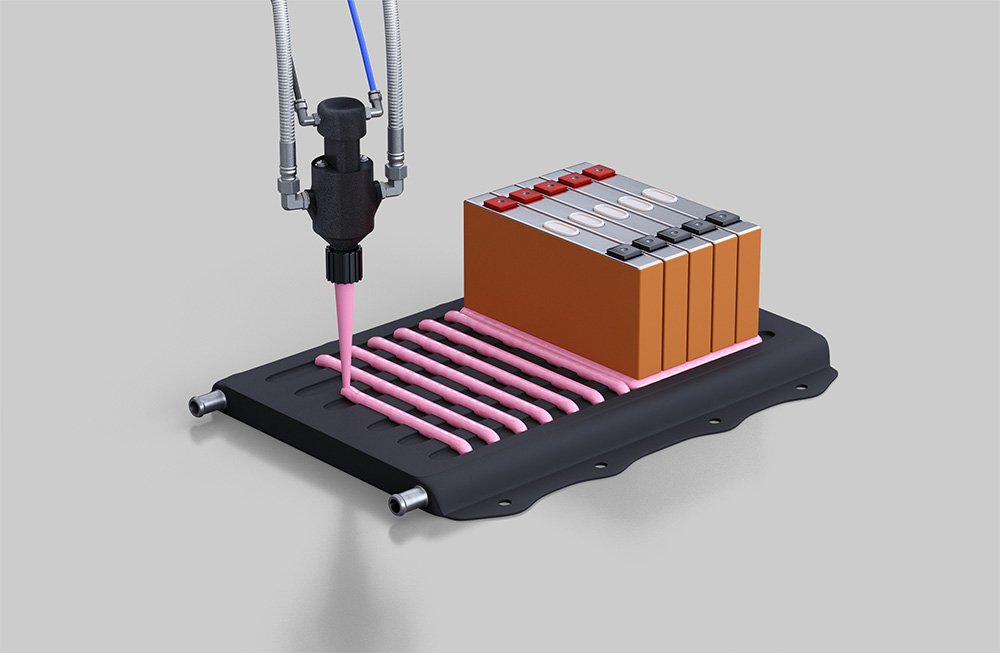

The concept car is equipped with a 100 kWh battery pack that AUDI parent company Audi says is good for up to 700 km of range (~430 miles) on the Chinese cycle. The wagon’s Advanced Digitized Platform also boasts an 800 volt system architecture that enables “super-fast” charging, adding more than 220 miles (370 km) of range just 10 minutes.

Electrek’s Take

Audi’s official press release says that the use of “AUDI” in lieu of the nearly century-old Auto Union rings “signals both the connection to, and differentiation from, the sister brand.” Now, call me cynical, but that seems both confusing and somewhat cowardly to me – if Audi wants to sell more affordable models in China under a different brand name, it already has one: Volkswagen.

Creating an AUDI that isn’t really an Audi is just bizarre, and I can’t imagine this move helping create the kind of positive energy that VW and Audi needs to dig themselves out of trouble.

SOURCE | IMAGES: Audi.

FTC: We use income earning auto affiliate links. More.

Source link by Electrek

Author Jo Borrás

#AUDI #ditches #rings #sexy #wagon #aesthetic