- Honda Ohio EV Hub will start making EVs in late 2025 on 0 Series platform

- Production will include Acura RSX, Honda 0 SUV, Honda 0 Saloon, and Afeela 1

- EVs, hybrids, and gas models will be mixed on single Marysville assembly line

- Processes introduced for EVs will apply to ICE models, making them better too

Over the past several years, a roller coaster of EV supply and market demand, with an about-face of regulatory moves, created a new kind of challenge for full-line automakers—about how deeply and how soon to commit to dedicated EV plants.

Honda continues to target 100% electric vehicle sales by 2040, and to have “zero environmental impact” by 2050. It’s previously projected 40% EV sales in North America by 2030. Meanwhile hybrids add up to 50% of U.S. Honda Accord sales, and in recent months Honda has admitted that it’s hard to predict the trajectory of where the mix will be on the way to fully electric.

To reconcile all this, it’s prepared by committing to a new template for making both EVs and gasoline models, all on the same production line. This sea change in how it makes vehicles could keep its oldest U.S. assembly plant, its Marysville, Ohio, facility that opened in 1982, humming at capacity, no matter what the market presents.

As Honda confirmed last April, Marysville will truly get the automaker to the point of EV mass production in North America, with a big asterisk. It has the capability to make hundreds of EVs per day, or many hundreds of gasoline models—depending on demand.

Marysville is one of four facilities set to make up what Honda is calling its Ohio EV Hub—including the Anna Engine Plant and East Liberty Auto Plant, all within 50 miles of each other, and a joint-venture battery plant between Honda and LG Energy solution in nearby Jeffersonville, Ohio. Battery plant aside, Honda says it encompasses more than a $1 billion investment in the three facilities, in redesigning the manufacturing process around being able to make ICE, hybrid, and EV models all on the same production line.

The investment in the Ohio facilities marks the global debut of changes in the way it builds vehicles, with expertise set to be shared across North America. And, according to Honda, it’s aiming to set a global standard for Honda EV production.

Acura Performance EV concept – RSX

Honda 0 SUV prototype

Honda 0 Saloon prototype

Honda is set to start electric vehicle production in late 2025 at the Ohio EV Hub, beginning with the Acura RSX EV. Honda-branded EVs based on the Honda 0 SUV and Honda 0 Saloon prototypes will arrive soon after, both in 2026.

That’s three models. There will also be a fourth model set to ramp up around the same time as those two Honda models: the Afeela 1, the Sony Honda Mobility (SHM) product of a joint venture between Sony and Honda. SHM confirmed last month at CES in Las Vegas that deliveries of the $89,900 Afeela 1 will start in mid-2026.

Afeela 1

Honda EVs, hybrids, and gas models, on the same line

At Marysville last week, Green Car Reports got to see this great change underway. Honda opted to combine its two assembly lines into a single flexible assembly plant concept. The project has been three years in the making behind the scenes, and Honda announced the project specific to the plant in March 2023.

The plant previously made the Acura Integra and TLX on one line, while the Accord was made on the other. Without interrupting the production flow (and temporarily moving Accord production at one point), that involved a series of transitions, with the added space allowing a much wider line, with a new sub-assembly strategy allowing for processes that EVs require and gas models don’t—and vice versa.

Honda Accord assembly at Marysville

Mike Fischer, the leader for Honda’s North American EV project, explained to GCR that this transformation of Ohio facilities is probably the single most important foundation for Honda manufacturing, moving forward, because it shows how Honda can maintain not just production flexibility but flexibility in how it keeps engineering and designing its vehicles. BEV and ICE vehicles can remain optimized for their respective strengths, and neither one will be hobbled for it on the manufacturing floor.

Honda is keeping the overall build time exactly the same after the line change, according to Fischer, who led the production launch of the 2013 Accord, which required some changes at the plant due to its extensive engineering changes like a strut layout, CVT automatic, and available hybrid versions. The upcoming BEV models and their subassemblies will take “a little bit” more build time than the current Accord, he said, adding that there’s still opportunity for optimization and it should be the same or maybe a little less.

Meanwhile, it’s picking up the pace on that one line such that total output from the plant could potentially reach the previous peak production of about 950 vehicles a day, or an annual capacity of 220,000 from two lines.

It was no easy task. The upcoming EVs, which we previewed in October with a Honda 0 Series prototype drive, are set to have very little in common with Honda’s gasoline vehicles, and they’re going to be fundamentally different for many years. Honda has no plans to merge body structures or vehicle platforms among its gasoline and hybrid models.

Honda 0 Series battery cases

Honda seeding the future in with its bread and butter

From the concept-car proportions to the next-gen Asimo OS interface, to all-new switchgear and displays, to the calibration needs of their Level 3 automated driving system, and everything underneath, it’s seriously hard to find commonalities. While the Accord’s structure is primarily steel, the EVs will be built on an aluminum-focused body structure, with the aluminum battery pack an integral piece. They were designed with different priorities—so as to have short overhangs and efficient cabins, with the force paths designed with no allowance for an engine in front, eliminating the need for high cowl crossmembers and sending force paths to thick side rails.

So it created a series of sub-assembly lines that could handle all the differences in the way an EV is assembled versus the way a gasoline or hybrid vehicle is assembled—and widened the way for those sub-assemblies and for parts and components to get through.

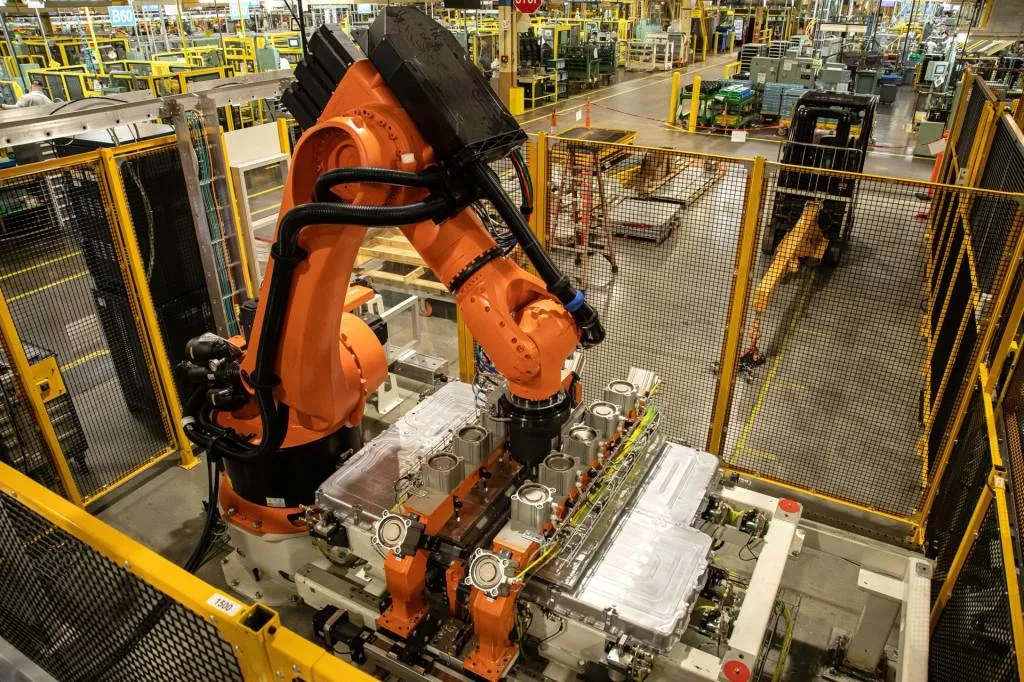

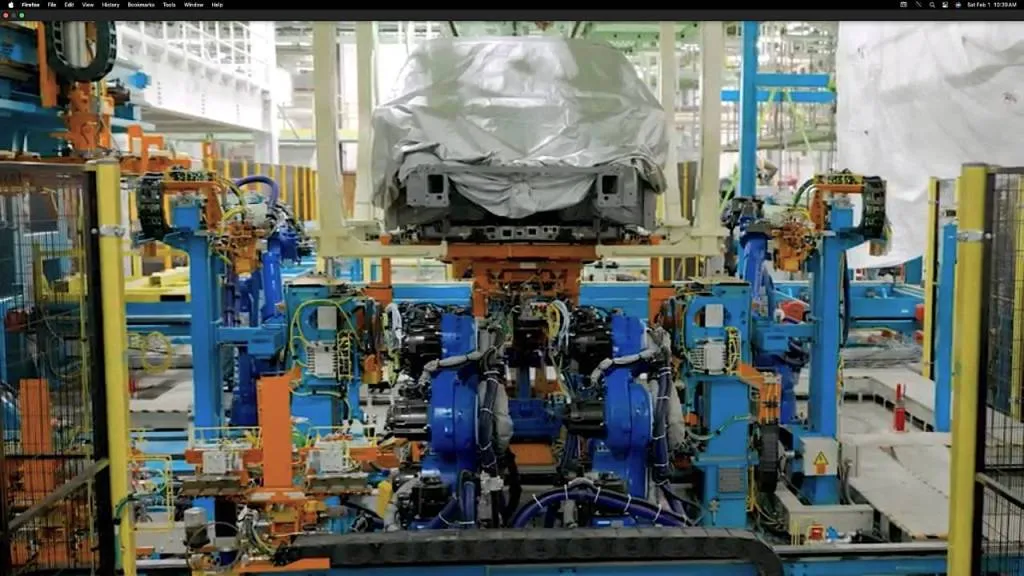

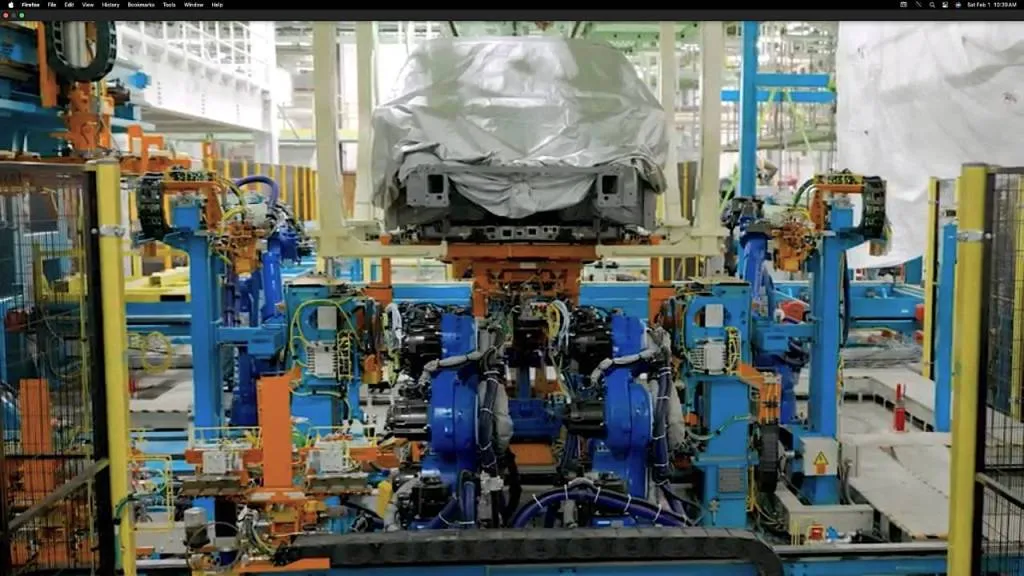

Honda had to upgrade its vehicle carriers for heavier EVs, redesigned its people-movers along the line for better ergonomics, and had to devise robots that would apply thermal gap filler to the pack on the vehicle line. It also had to design a process for battery pack assembly itself—including the installation of cells from the nearby Honda-LG battery plant—and for battery pack installation into the vehicle (below).

For the body structures of the new EVs, Honda is switching to a CDC weld technology—a world first, employing pulses rather than a constant current to help make a lighter, stronger structure. If you expect fireworks of sparks at welding stations, it feels uneventful.

Honda Accords going through inspection – Marysville OH

ICE and hybrid vehicles pass through the EV battery pack area without stopping, while EVs may pass through some of the steps for elements like exhaust and fuel-system installation without stopping. Honda calls it “multi-platform flexibility.” And to keep the rate of Accord Hybrid production running strong, Honda also created a new area for hybrid battery assembly.

LG pouch cells fill the modules that get installed into the EVs’ battery packs on the Marysville line, as we saw demonstrated, but Honda hasn’t yet confirmed the battery capacity. The pack is kept thin by Honda’s unusual and innovative cooling strategy—with water jackets machined into the pack case itself, allowing super-thin channels of coolant to circulate between that and a jacket cover that fits over it.

Honda 0 Series battery case – quenching after casting

Honda 0 Series battery pack

Friction stir welding of Honda 0 Series battery case halves

Honda’s engine plant pivots to packs—and maybe motors

Meanwhile, the packs themselves are set to be made less than an hour’s drive away, at Honda’s Anna Engine Plant, where it’s taking on a similar challenge: manufacturing some of the key components for the 0 Series’ battery pack and powertrain without interrupting its throughput for the range of engines—including Atkinson-cycle four-cylinders for the Accord Hybrid.

Honda has made about 30 million engines at Anna, and it has the production capacity to make more than 4,800 of them per day. Electric motors for the EVs, engineered by Honda but built by captive supplier Hitachi Astemo at present, are likely to be brought into Anna eventually, executives said.

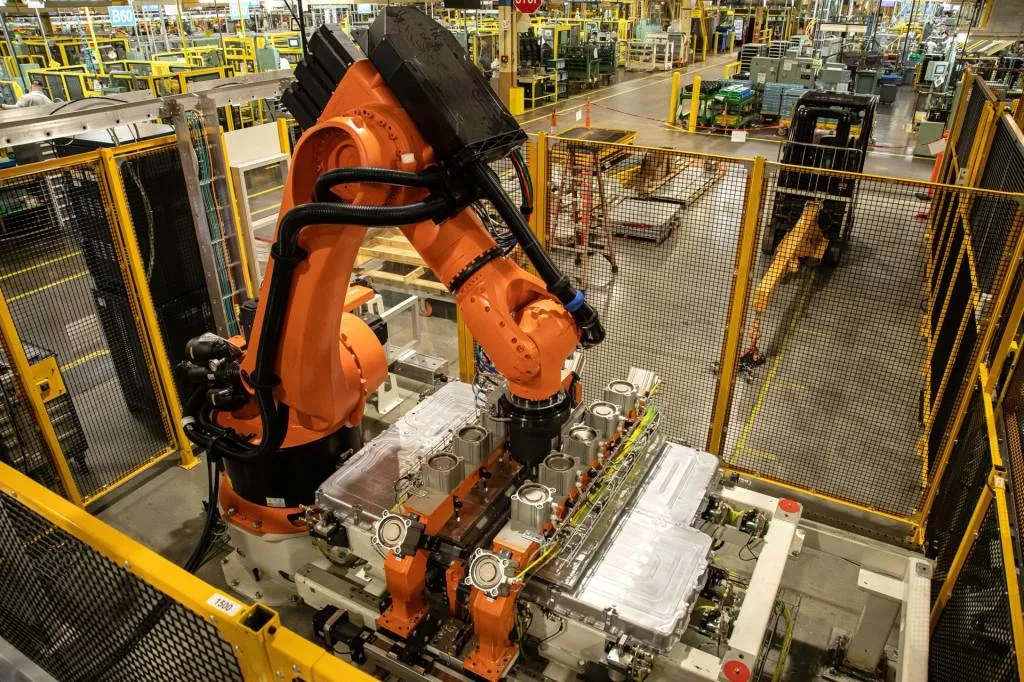

With six 31-foot-tall, 6,000-pound die-cast machines at Anna, Honda will “megacast” the battery-pack cases set to go into EVs at both Marysville and East Liberty. As Honda underscores, it’s larger than anything it’s ever die-cast.

Megacasting uses less energy than gigacasting, and the die-cast process reduces scrap, eliminates the need for heat treating, and enables Honda to shift the energy used in the process from gas to electricity—reducing the CO2 footprint.

In Honda’s EVs, the pack is split into a front and rear section, with a friction stir welding process—strongly joining the two pieces without melting—bonding the “butt joint” between the two sections.

Prior to machining, to make sure the cases, which serve as part of the structure of the EVs, are dimensionally in check—and, given the shape, that it’s stayed flat—Honda has put to use a new “photogrammery” method potentially employing more than 100 cameras that rapidly take a series of photos of the part, reconciling all the recorded geometries.

Honda Accord Hybrid component assembly – Marysville, Ohio

Higher-quality Hondas all around from revamp

As Fischer suggested from an engineering standpoint, the meticulous look at how vehicles are being built, that went into this project, meant more than EVs on the same line plus updated machines and new robotics. It will benefit future gasoline, hybrid, and plug-in hybrid vehicles in a multitude of ways.

Tim Leopold, the BEV project lead for the Marysville plant, said that it’s brought in more of a “big data” approach to production starting with the EV Hub remake, that extends to EVs and gasoline models alike. It brought in a layered quality approach that’s so extensive it connects everything from the torque feedback of the tools used to tighten bolts to things like the dimensional accuracy of the bodies and how components fit together.

“We can either trace or track it with data, and control it to the point of an interlock where that particular unit won’t be able to pass downstream unless we get a system saying, it’s okay, I’ve received good data,” explained Leopold. “We’re using the EVs as an opportunity for change, but at the same time that change is going to help the ICE or hybrid counterpart, which is pretty exciting.”

Honda 0 Series prototype and battery pack marriage – Ohio EV Hub

EV production starts late 2025

Leopold said that Marysville is only about a month away from making so-called “trial production” versions of the first EVs, after which—with lots of analysis along the way—it will go through multiple iterations over the next 10 to 11 months leading to mass production.

This market-dependent, flexible, lift-all-boats approach is a necessary piece for remaining competitive over the next 12 to 15 years. Some of the way there it may simply become a question of when to retire the gasoline models. We aren’t there yet.

Now it’s a matter of proving the idea out in real-world manufacturing—a project that the team behind it feels very confident in taking around the globe.

“I can translate this, shift it to any of our manufacturing body plant operations,” said Fischer. “How to do ICE, hybrid, and BEV in general, together…It created the perfect storm for us to be able to do this at two facilities from the start, and then it will go wider.”

Source link by Green Car Reports

Author news@greencarreports.com (Bengt Halvorson)

#Honda039s #radical #EVs #Accords