When Tesla’s CEO chose to disband the company’s Supercharger team, EV industry pundits predicted that many of those experts would soon be snapped up by other firms. Now we learn that rideshare/charging provider Revel has hired Edward Noseworthy to lead the company’s EV infrastructure design and construction team. Noseworthy, a seven-year Tesla veteran who oversaw … Continue reading “Charging/rideshare provider Revel hires former Tesla Supercharger exec”

Headlining today’s Green Deals is the return of the Worx Landroid S 20V Robotic Lawn Mower at $700. It is joined by two one-day sales from Best Buy, the first being Anker’s SOLIX 522 Powerhouse Portable Power Station for $189, as well as the 17-foot Rexing J1772 Extension Charging Cable at $110. Plus, all the … Continue reading “Save $300 on Worx’s Landroid robot mower, 1-day sales on Anker 522 Powerhouse and Rexing EV charger extension cable, more”

Sponsored by Henkel. With an innovative approach to lithium-ion battery electrode manufacturing, dry battery electrode (DBE) processing eliminates the solvent-based slurries traditionally used in lithium-ion battery production. By implementing DBE technology, battery manufacturers can enhance production efficiency, reduce energy demand, and decrease overall environmental impact while improving electrode performance and reducing battery production costs. DBE … Continue reading “Enabling dry battery cell manufacturing with conductive coatings (Whitepaper)”

Cadillac has revealed an entry EV for the GM luxury brand that doesn’t seem so entry-level in size, technology, or price. The 2025 Cadillac Optiq is set to cost about $54,000 including destination when it arrives later this year with a range of around 300 miles, according to Cadillac. While that price tag won’t be … Continue reading “2025 Cadillac Optiq EV pivots to Millennials, goes soft on Art & Science”

A new all-electric maritime specialist called Vessev has come out of stealth mode with an exciting new vessel called the VS—9. The electric hydrofoil boat offers a state-of-the-art design that delivers incredible efficiency, providing future tourists with a smooth and quiet ride as Vessev looks to commercialize into larger vessels that can transport 100 passengers … Continue reading “Meet Vessev and its ultra-efficient electric hydrofoil boat designed for smooth tourist rides”

Japanese engineering plastics manufacturer Polyplastics has launched a new glass-filled polyphenylene sulfide (PPS) grade that meets the requirements for metal insert molding, particularly for EV busbars. The DURAFIDE PPS 1140HS6 is designed to limit molding imperfections and enhance performance without the need for impact modifiers in EV busbar applications. Insert-molded EV components are typically made … Continue reading “Polyplastics launches PPS grade for EVs”

Let’s just face it, America. We’ve got a weight problem. No, not that weight problem. It’s the size of the cars. The best-selling vehicles in the US are all of the biggest, heaviest, and most oversized models available. But it doesn’t have to be that way. A new crop of tiny electric cars is changing … Continue reading “Why this electric ‘car’ the size of two motorcycles should be on your list”

Volkswagen on Tuesday announced a goal of launching an EV priced at 20,000 euros—equivalent to $22,000 at current exchange rates—in 2027. This affordable EV is aimed at the European market, with a high degree of manufacturing and supply-chain localization entailed in the project, VW said in a press release. This will allow for shorter transportation … Continue reading “VW plans 2027 debut for $22,000 EV for Europe, beyond”

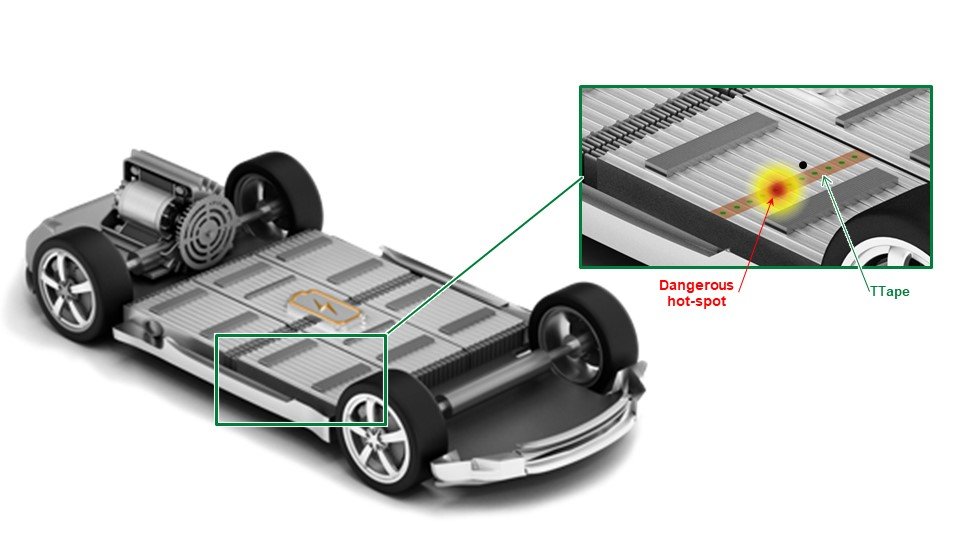

Innovative product pinpoints EV battery hotspots, improves safety and extends battery life Lithium batteries offer the highest power density compared with other battery chemistries. Lithium batteries can store more energy in a smaller, lightweight package than any other type of battery. As a result, Lithium-based batteries are the battery type of choice for all types … Continue reading “New technology platform enhances performance and lifespan of EV batteries”

A new Hyundai three-row electric SUV is set to hit the US market. Ahead of its official debut, the Hyundai IONIQ 9 was caught testing in the US. From the looks of it, the electric SUV looks even bigger and bolder in person. Hyundai is already outpacing rivals in the US with its wide-ranging lineup … Continue reading “Hyundai’s new IONIQ 9 electric SUV looks even bigger in latest US testing video”